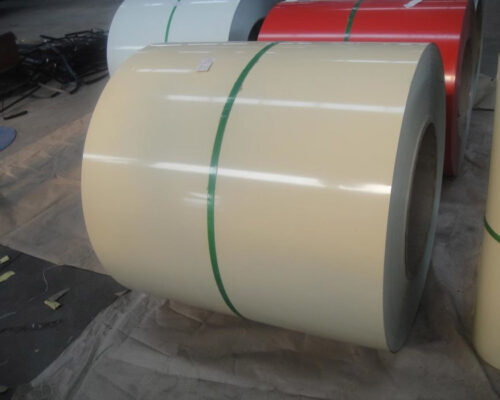

Top PPGI Coil UAE Supplier for Robust Infrastructure Development

The infrastructure of UAE is growing rapidly due to the robust PPGI Coil UAE and quality materials like corrugated fencing, perimeter fencing, sandwich panels, GI sheets, steel pipes, tubes, etc. However, building a robust property needs infrastructure material and assistance from an experienced team that can use PPGI Coil UAE in a way that can improve the quality of the construction.

Send Enquiry

What Are the Role of PPGI Coils in UAE Development?

A PPGI Coil is a product made of steel wire. It is protected with a coating of paint so that it does not get rust. However, the product is used in the construction of buildings, transportation sectors, and roofs. It is galvanized iron that is painted so that it can withstand tough weather and different climates.

Meanwhile, the industry demands that PPGI Coil strengthen the UAE’s infrastructure to boost the country’s economy and emerge as the best place to live and thrive.

Advantages of PPGI Coil and Its Use

Galvanized iron coils are famously known for their lasting quality and strength. However, replacing coils has many different alternatives such as metal sheets. It is a mix of quality and strength that offers robustness while building infrastructures.

Metal n Machine PPGI Coil can produce more safety than the ordinary one because it does generate hazardous waste to harm the environment and even nature. Therefore, we as a company are known as the best PPGI Coil producer in the Gulf.

Galvanized PPGI coils are appreciated for their versatility and durability. However, pre-painted coils do not corrode easily and function perfectly in tough weather and unpredictable climates. These coils are used in many heavy-duty security applications and are in demand in UAE.

Using pre-painted galvanized coils is helping in building and large machinery production.

However, the process involves immersion of steel substrate in boiling zinc. It then acquires circulated metallic particles for non-breakability from natural calamities. Thus, making it the best for construction works.

Understand the Galvanization Process and the Role of PPGI Coils in Rust Prevention and Longevity

The PPGI Coil goes through the entire process of galvanization. During galvanization, steel is coated by a considerable layer of zinc, protecting it from corrosion. If you are wonderful, how many methods are there for galvanizing? Well, there are two:

World-renowned Hot-Dip Galvanization

Preparation for Chemical Dip: PPGI coils or sheets are cleaned, removing oil, dirt, and rust. They are then pickled in an acid bath to remove any remaining oxides and mill scale. This is part of surface preparation. Then the clean steel coils are dipped in a bath of molten zinc at temperatures from 815°C to 860°C. Because of the temperature, the molten zinc reacts with the steel’s surface, leading to a metallurgical bond between the zinc and steel. It makes the coating thick and tough.

Ensure Cooling and Quality Control

A galvanized steel coating is air-cooled to ensure the zinc coating is solid and thick enough to withstand heat. Afterward, various quality inspections confer the uniformity of the zinc coating and confirm any defects.

Hot-dip galvanizing is well regarded for its efficiency in providing a strong, durable coating resistant to corrosion.

What is the Process of Galvanized PPGI Coils for Rust Protection?

Galvanized PPGI Coil UAE-made are coated for rust protection and to enhance the longevity of products and structures. Here is a process through which it goes through:

Expert Galvanization Process

Galvanized steel coils are obtained by a process called galvanization whereby zinc is applied in a coating form over the surface of the steel. In most cases, the process used is hot-dipping, whereby the steel substrate is dipped in a molten bath of zinc. An alternate method is electroplating.

Optimized Zinc’s Sacrificial Protection

Because it is very reactive to environmental influences like moisture and oxygen, zinc is selected. When steel is coated with zinc, a protective layer is formed. This layer is sacrificial, which means that when the substrate beneath is exposed to corrosive elements, it will be the first to corrode and become the protective barrier for that steel. Hence, no rust forms on the surface of steel.

Highly Protected Corrosion Resistance Process

Zinc has excellent corrosion resistance. It enables steel in severely caustic environments, be it marine or industrial work wonderfully. The coating of zinc will act as a physical barrier to prevent moisture and oxygen from coming into contact with the steel, which are the root causes of rust formation.

How Coating PPGI Coil Gets Its Longevity and Why is It Best in the UAE Market?

Galvanized steel products live almost three times longer than untreated steel. These are tailored to remain free from rust and corrosion for years without any maintenance checks. Due to this quality, galvanized steel rolls ideally find application in outdoor structures, pipelines, automotive components, etc., where longevity and longevity are called for.

Low maintenance of galvanized steel contributes to its long life. Untreated steel would get rusty if not painted or coated regularly to prevent that. However, with galvanized steel, rust is not a problem for the life of the steel, leaving regular maintenance unburdened from it. This saves not just time but also money.

PPGI Coils have a good opportunity to formulate in Dubai. Its zinc coating prevents rusting and increases longevity by acting as a sacrificial ball, thereby preventing corrosion from reaching the steel substrate. Because of these properties, galvanized steel has become a choice favored by multiple industrial sectors where corrosion resistance and longevity are very important.

Meanwhile, if you are looking for the best PPGI Coil UAE for construction purposes, you can contact Metal n Machine without any delay and approach product delivery.

How PPGI coils/ steels are prepared?

PPGI is mainly prepared by continuous dipping the galvanized steel in a hot-dip zinc mixture. This coating of metal provides strong corrosion protection to metals. It provides cathodic and barrier protection to the base steel significantly reduces the corrosion rate. This led to an increase in the durability of the products. The product gets the strength to fight with this aggressive atmosphere.

Application of Prepainted Galvanized Steel Coil:

- Construction of building: roofing; ventilating duct; handrail; partition panel; etc.

- In the manufacture of Electric appliances such as refrigerator; washing machine; microwave; etc.

- Transportation: oil tank; road sign; etc.

- Agriculture: barn; etc.

- Others: vending machine; game machine; etc.

What is the advantage and disadvantage of galvanized coil in UAE?

- Strong Corrosion Resistance

The zinc layer on the surface of galvanized coil in UAE has great anti-corrosion properties that can viably stand up to outside components such as wind disintegration or corrosive rain erosion.

- Long Service Life

After being treated with the Gi coil in UAE and PPGI coil UAE handle, the benefit life span can be more than twice that compared to untreated steel materials, significantly increasing their durability.

- High Safety and Security Performance

Galvanized coils not only have great anti-corrosion properties but also great flame-retardant execution, making them widely utilized in the prefabricated steel building in the UAE industry.

- Good Environmental Security and Safety Performance

During the generation process, there may be a little squander gas, squander water, or squander buildup created from creating these items; in any case, cutting-edge innovation permits us to meet natural measures without contaminating our environment.

We offer you a variety of steel products to satisfy all your requirements. Let us know if you need any of the metal products from our ends. We glad to deliver you custom-manufactured coils and sheets at your service. If you need Sandwich Panel in UAE you can make a call to our experts’ team, they will definitely revert you back. You will find a reasonable price for each product. Contact us for any support and services.